Given the realities of working life, a bodge job can beat the company’s purchasing protocols, advises Matthew Partridge.

Science is not getting cheaper. It never really has, as new advancements often require new equipment, new techniques, and new computers (in research, a ‘new’ computer is any model made after 2010). And science budgets aren’t getting any bigger. So, as researchers, what are we to do? Well, that’s simple: we campaign for more funding, vote for science-positive politicians, join and support local unions, and work to help educate the wider public about the value of science. Like I said, simple.

Except all of those solutions are long term and require a slow, concerted effort from the entire community. And while they may bring about change, they are unlikely to do so between now and the time when your grant runs out, and you have no data.

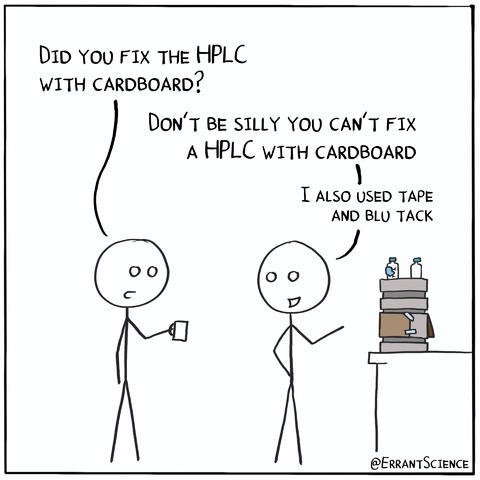

So a better question is, as researchers, what are we meant to do when staring down the barrel of a deadline and looking at an inexplicable error message on some very expensive kit? Well, that’s also simple: bodge it.

Now if you’re unsure about bodging your expensive and complex scientific kit, then first off, let me put your mind at ease; it’s already been bodged

For those not familiar with the term, ‘bodge’ is a Middle English word that means to repair, patch, or fix in a somewhat inelegant way. The key difference between repair and bodge is that a bodge is something generally repaired by someone who hasn’t got a clue what they’re doing but is trying anyway. It is sometimes also used to mean a repair that is rubbish or a ‘botch’. And while many bodges might end up being botches, enough are brilliant strokes of genius, balancing it out.

Which very much sounds like the position that many researchers find themselves in. Not having a clue what they are doing but standing in front of some very complicated kit faced with one of two options: find more money to fix it or... bodge it.

Now if you’re unsure about bodging your expensive and complex scientific kit, then first off, let me put your mind at ease; it’s already been bodged. Having been involved in the development and production of scientific equipment, I can tell you that you’d be surprised how much of it is already built from things that have been bodged. Fancier AutoCAD-based bodging masquerading as a “design feature” but bodging nonetheless.

Besides, it’s often not as complex as you’d expect. The vast majority of scientific equipment is not made in some ultra-precision, ultracontrolled factory. The chips and optics might be, but the rest is hand-assembled by some nice person in a small industrial park in Tunbridge Wells. Open it up, and you’ll find it’s surprisingly sensibly laid out, and sometimes the fix is as simple as reconnecting a cable that they forgot to attach a small locking clip to because it was almost lunchtime and the sandwich van was pulling up outside.

So with that in mind, get opening things up, start investigating, and start bodging. Even if you are one day lucky enough to work in a wellfunded lab (e.g., Blue Moon Inc or Impossible Madeup Ltd), then all of the above is still vitally important because nine times out of 10, bodging something is always faster than trying to get through the purchasing procedures, and 10 times out of 10, it requires less paperwork.

Dr Matthew Partridge is a researcher, cartoonist and writer who runs the outreach blog errantscience.com and edits our sister title, Lab Horizons