Reversible composite adhesives offer new possibilities in material science

14 Mar 2025

Researchers have created reversible composite adhesives using molecular entanglement, enabling enhanced performance, recyclability, and innovative applications across automotive, aerospace industries, and beyond.

Composite adhesives such as epoxy resins are indispensable in modern manufacturing, widely used to join or fill materials like wood, metal, and concrete due to their exceptional durability and strength. However, their permanence presents a significant drawback, as once hardened, these adhesives typically cannot be altered or reversed.

Now, a team of researchers from Lawrence Berkeley National Laboratory has developed a novel reversible adhesive, opening new possibilities for composite material design and recycling.

The research team, led by Dr Ting Xu, recently published their findings in Advanced Materials. Their groundbreaking approach employs the concept of molecular entanglement rather than traditional permanent chemical bonding. This creates reversible "pseudo-bonds" that offer new flexibility in applications traditionally limited by the permanence of conventional composite materials.

In conventional composite adhesives, permanent chemical bonds between molecules contribute to their renowned durability and strength. However, these bonds also mean the composites are effectively irreversible, limiting their use where adaptability or recyclability is required.

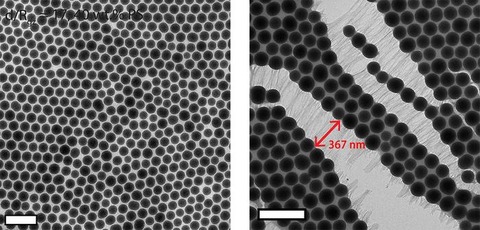

The new method leverages molecular entanglement—similar to the structural principle of protein folding—to create robust yet reversible structures. By using a system of polystyrene chains attached to silica nanoparticles, researchers successfully controlled how polymer chains entangle within defined nanoconfined spaces.

The approach can be visualised as akin to untangling a ball of yarn, where the polymer chains are carefully arranged within small, confined spaces to control their level of entanglement. By adjusting the length of the polystyrene chains and their attachment positions on silica nanoparticles, the researchers precisely engineered how the composite dissipates mechanical stresses and achieves remarkable load-bearing capabilities. This meticulous control resulted in materials whose properties could be deliberately tailored, offering increased load-bearing capacity and enhanced resilience.

Microscopy studies confirmed the significant impact of controlled entanglement. By systematically varying chain size and attachment points on silica nanoparticles, the team increased the composites' load-bearing capabilities by up to 50%. These adjustments allowed the composite to respond dynamically to external stresses, providing superior performance under mechanical load compared to traditionally bonded materials.

The research marks a notable advancement in the field, showcasing the potential of nanoconfinement as a powerful tool for organising amorphous polymers, which traditionally lack the precise structural order of biological molecules such as proteins. This achievement represents a substantial step forward in polymer science, offering new potential for materials to be precisely engineered for specific mechanical and structural properties.

Critically, the technology's reversibility introduces new opportunities for recycling and reusing composite materials, addressing significant environmental concerns associated with traditional permanent adhesives.

Such reversible composites could be particularly beneficial in fields like automotive, aerospace, and construction, where materials are frequently replaced or repaired, significantly reducing waste. Future studies will likely focus on testing other polymer and nanoparticle combinations, potentially leading to widespread adoption across various industries.

Pic: Tiffany Chen; Ting Zu